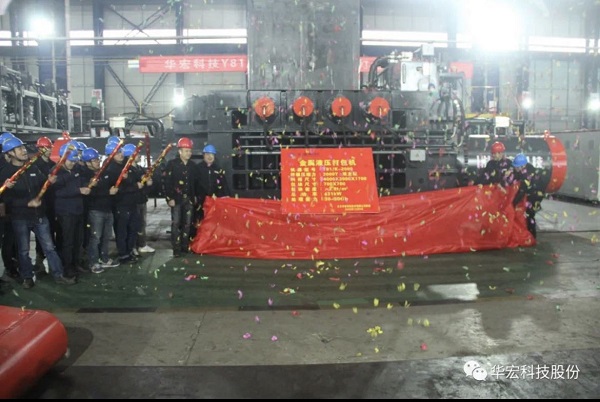

In the afternoon of December 9, 2020, Jiangsu Huahong Technology Co., Ltd. held a "2000T baler and gantry shear off-line ceremony" in the heavy equipment workshop.

Lu Kaike, vice president of production, presided over the ceremony. Hu Pinlong, general manager, Chen Fangming, vice president of sales, Huang Jiansheng, vice president of technology, Lu Yongwei, vice chief engineer, as well as the relevant persons in charge of technical research and development line, production line, workshop director, quality inspection center, personnel and administrative department, after-sales service center and other relevant persons attended the ceremony.

Vice president of production presided over the launching ceremony

General manager made an important speech

Hu Pinlong, Chen Fangming, Huang Jiansheng and Lu Yongwei unveiled the machine

Y81/K-2000 double main cylinder type metal baling hydraulic press, especially solves the problem of difficult baling and compression of large heavy scrap steel such as cutting ship plate material and steel template and low density of bales.

Innovation points.

1. innovative design of main pressure cylinder seat and door cover cylinder seat structure, which saves processing cost and improves reliability.

2. Automatic lubrication device between liners, which greatly improves the service life of liners and saves maintenance cost and time.

3. The innovative design of servo electro-hydraulic control system is the first in this industry, which makes the operation of the equipment more efficient, smooth and energy-saving.

The main parameters are: maximum baling force 2000 tons; material box size 4000�3000�1700; bale size 700�700; bale density ≥2.8t/m3; production capacity 30-50t/h.

Q91Y-2000W hydraulic scrap steel shearing machine especially solves the problem that the high-density steel bales (density 2-2.5t/m3) pressed by balers above 1000 tons cannot be sheared.

Innovation points.

1. the adoption of a fast scrap steel shear hydraulic circuit system, through the layout of the two-way switching valve and reversing valve in the original hydraulic system, the optimization of the hydraulic circuit, the realization of the press cylinder and shear cylinder linkage, reducing the return waiting time and improving the shear efficiency.

2. innovative design of large hydraulic cylinder structure, adopting new snap-ring connection structure, two-point positioning of cylinder front and rear, improving structural reliability and stability, facilitating disassembly and installation, reducing installation difficulties and maintenance costs.

3. The first innovative design in the industry using servo electro-hydraulic control system, so that the operation of the equipment more efficient, more stable, more energy efficient.

The main parameters are: maximum shear force of 2000 tons; knife length of 2 meters; shear frequency: ≥ 3 times / min; production capacity of up to 50t / h.

Home

Home  About us

About us Partner

Partner  Products

Products News

News Certificate

Certificate Contact Us

Contact Us